What was the reason for joining the company?

I have loved manufacturing and mechanical things since I was young, and in high school, I was part of the robotics club, participating in competitions with robots we designed and built ourselves. Given my background as a student, I naturally focused my job search on manufacturing companies. As a result, the company introduced to me by my teacher was Trix.

What is your current job?

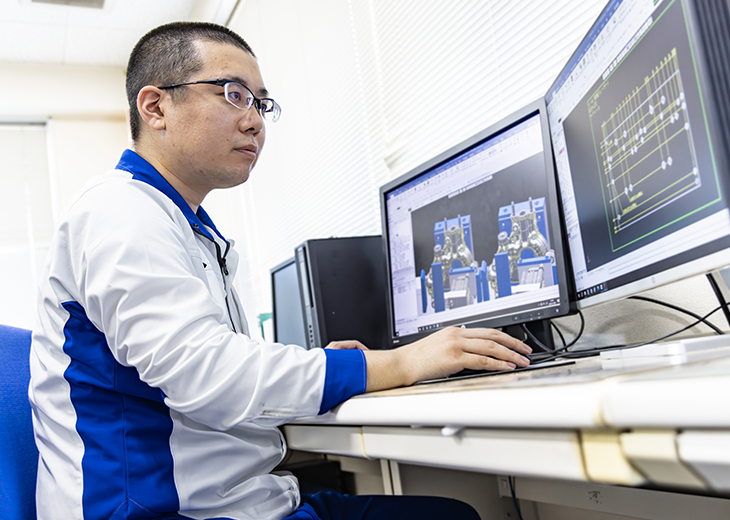

After joining the company, I was assigned to the welding department and gained on-site experience as a welder. Subsequently, I was entrusted with a production technology position in the welding department to utilize the experience I had acquired. Specifically, I work on launching new equipment related to welding, renovating existing equipment, and designing jigs tailored to each manufactured item, constantly brainstorming to ensure the welding department produces high-quality and highly productive products. The production technology role encompasses a wide range of tasks, including machine and electrical design work, robot teaching to operate robots, and hands-on fabrication work to create jigs from materials, making it an irresistible environment for someone like me who loves manufacturing.

About the sense of fulfillment

Using my ingenuity to design, create, operate machines, and continuously improve is almost the same feeling I had when I was deeply involved in the robotics club in high school (laughs). That's why I believe this job is my calling. During the launch of new equipment, there are times when the development deadline is approaching and things just aren't going well, making it really tough as I can't see the goal, but when I can successfully complete the project with ideas from my boss and colleagues, I feel a great sense of achievement. Recently, I've particularly enjoyed the teaching work of making robots learn movements. People on site often say, 'Your robot moves aggressively in the shortest distance, doesn't it?' (laughs). Teaching brings out individuality.

Regarding future goals

As automotive parts become more complex and modular, the control of robots and machines is also becoming more complicated. In order to keep up with this trend, I would like to deepen my knowledge not only of machinery but also of sequence control.