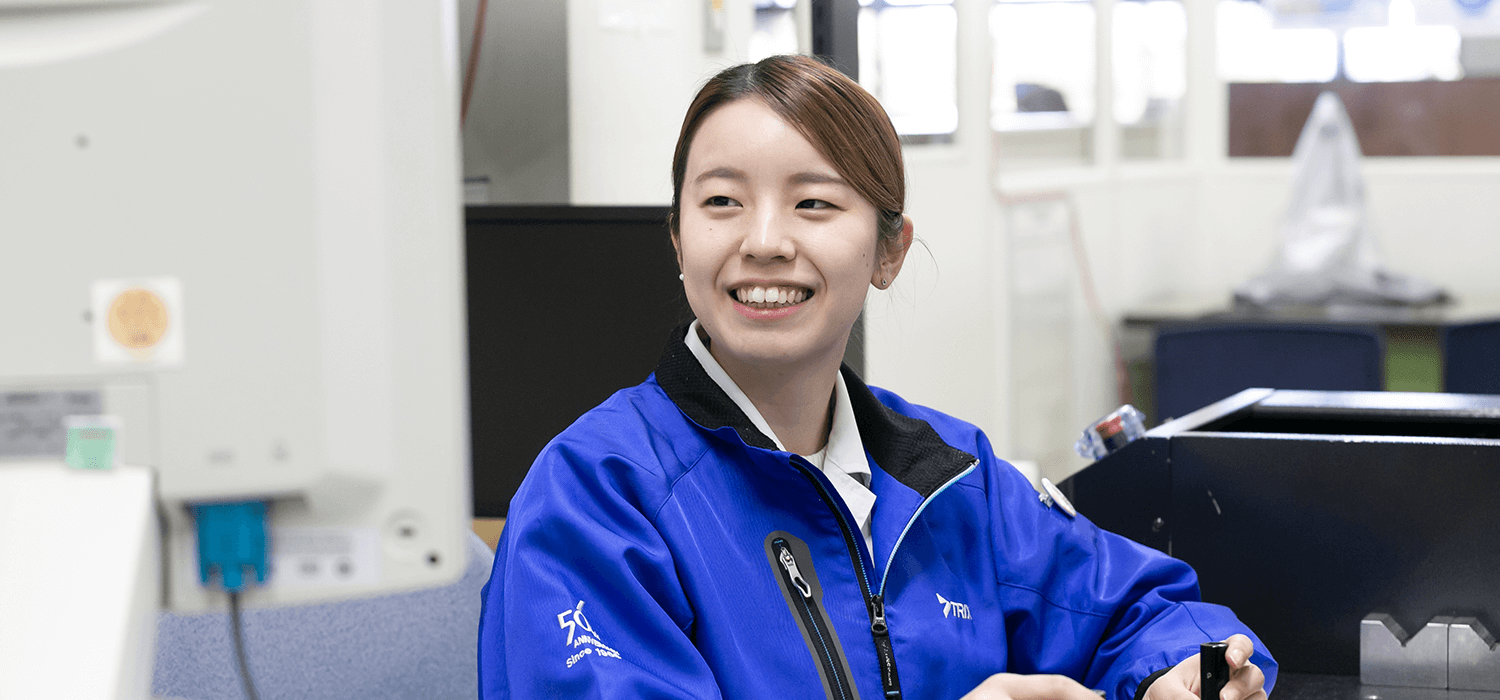

What was the reason for joining the company?

I chose Trix because it was a company where I could work locally for a long time. At first, I wanted to do office work, but I was assigned to the welding department. After that, I transferred to the painting department and then to the production technology department, and in 2021, I became a member of the team that launched the current department (manufacturing system development) and was entrusted with the work of an in-house system engineer.

What is your current job?

We are involved in the development and operation of the production systems used by employees on the production floor. We are particularly focused on visualizing the production site. We collect data from each process on the production floor and display the current production volume and equipment operating status on a display panel. Additionally, by obtaining historical information on when, who, and which terminal registered the information, we achieve traceability and strengthen quality control. Furthermore, we design and manufacture various sensors to automatically collect production status. We are constantly thinking about and implementing what can be done with the system to increase production efficiency by making it easier to identify losses and reducing the workforce on the production floor.

About the sense of fulfillment

When various information obtained from the site becomes visible in numbers, it can be used to improve production efficiency, enhance quality, and benefit management. Being said "thank you" for doing so is rewarding. The more my IT skills improve, the higher the level of systems I can realize, so there is a challenge of continuous self-growth, but in my case, it doesn't feel like a hardship because I am strongly engaged in something I enjoy. Since I had no experience in system development at all, I started by researching programming languages online and creating apps through self-study, but as I saw the systems actually working, it gradually became more interesting. Being able to constantly challenge myself with new things while thinking about various aspects is also rewarding.

Regarding future goals

We want to contribute to profitable factory operations and the production of high-quality products with our IT skills. In addition to systems, we are also creating IT modules tailored to our own factory specifications, so we want to promote our own IoT that includes not only development but also manufacturing. In the future, it would be great to compile this know-how and sell it to other companies.