1. Assembly line utilizing 37 years of know-how

Based on the know-how we have cultivated over the past 37 years since we received the first order for domestic and foreign parts from Honda Motor Suzuka Manufacturing Engine Assembly in 1986, we are engaged in stable operations ranging from parts management, assembly, inspection, and shipment correspondence.

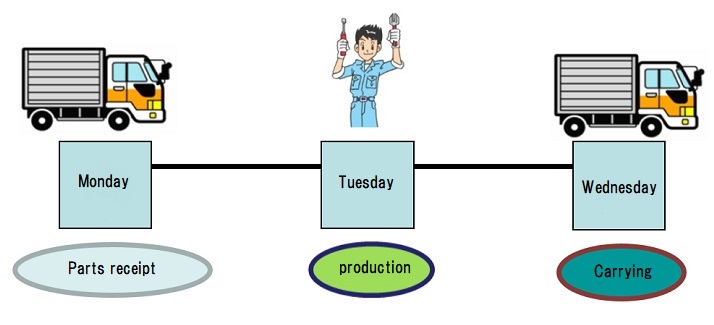

There are many parts and synchronous deliveries, and the Inmani ASSY representative parts are delivered approximately every hour by synchronous delivery linked to the production of engine assembly. The number of units delivered by sorting each engine assembly in order of production also reached approximately 16.47 million units in 37 years. The production site does not have any inventory, and we maintain high quality by conducting careful and reliable work with a production system led by women. In addition, since the contact point and the site are closely related, we respond flexibly and promptly to customer requests.

There are many parts and synchronous deliveries, and the Inmani ASSY representative parts are delivered approximately every hour by synchronous delivery linked to the production of engine assembly. The number of units delivered by sorting each engine assembly in order of production also reached approximately 16.47 million units in 37 years. The production site does not have any inventory, and we maintain high quality by conducting careful and reliable work with a production system led by women. In addition, since the contact point and the site are closely related, we respond flexibly and promptly to customer requests.

2. Clean working environment

There are many engine parts, and we pay attention to dust prevention in the workshop.

In particular, the assembly building for mission parts has double doors and is an excellent dust-proof environment, and it is also possible to respond to the strict clean requirements of customers.

In particular, the assembly building for mission parts has double doors and is an excellent dust-proof environment, and it is also possible to respond to the strict clean requirements of customers.