1. A stable assembly line backed by 37 years of proven expertise.

Since receiving our first order for internal and external components from Honda Motor Co., Ltd. Suzuka Factory’s engine assembly division in 1986, we have built a stable and integrated operation over the past 37 years—covering parts management, assembly, inspection, and shipping—by leveraging our accumulated expertise.

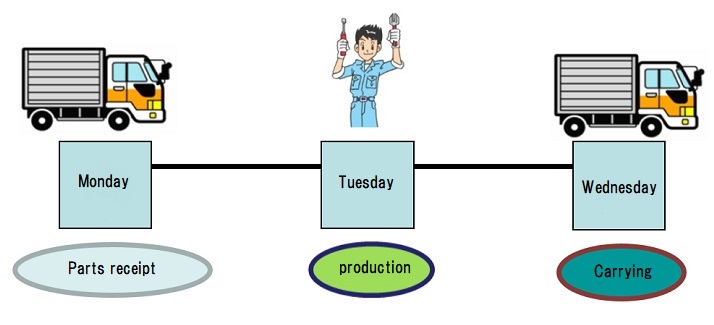

Key components such as the intake manifold assembly (Inmani ASSY) are delivered in sync with the engine assembly production schedule, approximately every hour. Each unit is sorted according to the production sequence, resulting in a total of approximately 16.47 million units delivered to date.

Our production site operates without inventory, maintaining high quality through a careful and reliable production system led primarily by women. Furthermore, close coordination between our customer service and production teams enables flexible and prompt responses to customer needs.

2.A clean and well-maintained work environment with thorough hygiene management.

Due to the large number of engine components handled at our facility, we pay meticulous attention to dust control.

In particular, the assembly building for transmission components is equipped with a double-door structure, creating a clean environment that effectively prevents the intrusion of external dust particles. This setup enables us to fully meet even the most stringent cleanliness standards required by our clients.

In particular, the assembly building for transmission components is equipped with a double-door structure, creating a clean environment that effectively prevents the intrusion of external dust particles. This setup enables us to fully meet even the most stringent cleanliness standards required by our clients.